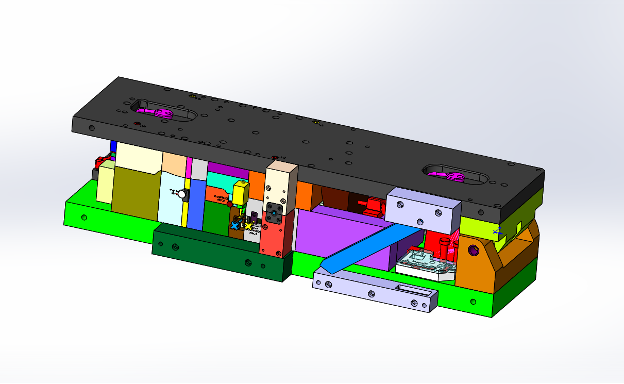

Our engineering team is the foundation of every successful project. Using advanced CAD systems and deep industry experience, we design high quality investment casting tooling that optimize performance, manufacturability, and cost efficiency.

Capabilities include:

Our engineers work closely with clients to translate concepts into precise, production-ready designs that meet exact specifications.

Precision machining is at the heart of what we do. MDF Tool Corp’s shop is equipped with CNC milling and Sinker EDM technology, enabling us to handle complex geometries and tight tolerances with confidence.

Capabilities Include:

Every part we produce reflects our commitment to accuracy, repeatability, and efficiency.

MDF Tool Corp’s legacy is built on superior craftsmanship in tool making. From custom jigs and fixtures to complex dies and molds, our toolmakers deliver solutions that enhance production performance and product consistency.

Capabilities Include:

Each tool we produce is built to perform under demanding production conditions, ensuring long-term reliability and precision.

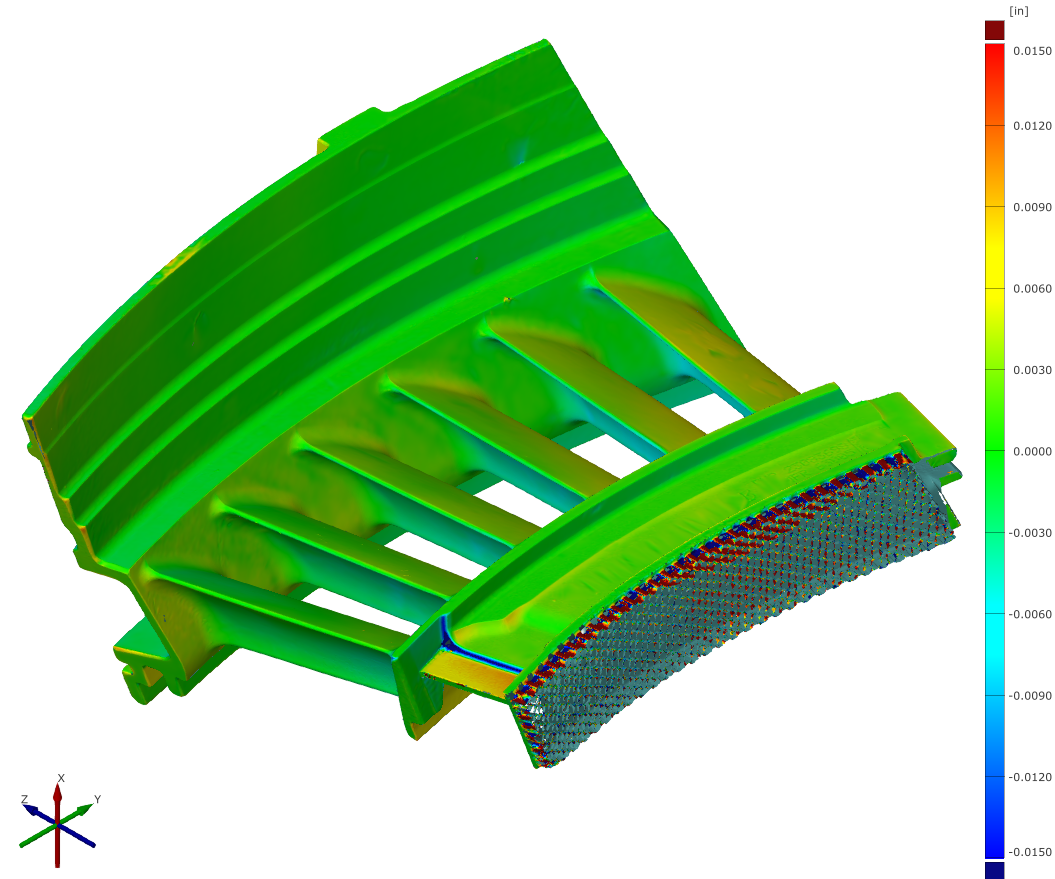

Quality assurance is built into every stage of our process. Our inspection capabilities ensure all components meet exact specifications and tolerances for our tooling. With our top of the line Zeiss ATOS Q Blue Light 3D Scanner, we provide high-accuracy inspections for in-house manufacturing, single-part scanning services, and complete reverse-engineering needs.

Capabilities Include:

We maintain documentation and inspection procedures to guarantee the integrity and precision of every part.

At MDF Tool Corp., we design and build precision tooling for the investment casting industry. With decades of experience in engineering, machining, tool making, and inspection, our team supports leading manufacturers in aerospace, energy, and industrial applications — delivering accuracy, repeatability, and reliability.

Let’s talk about your tooling needs and see how our experience can bring your designs to life - on time and to spec.